- Ninomiya System Co., Ltd.

- PRODUCT

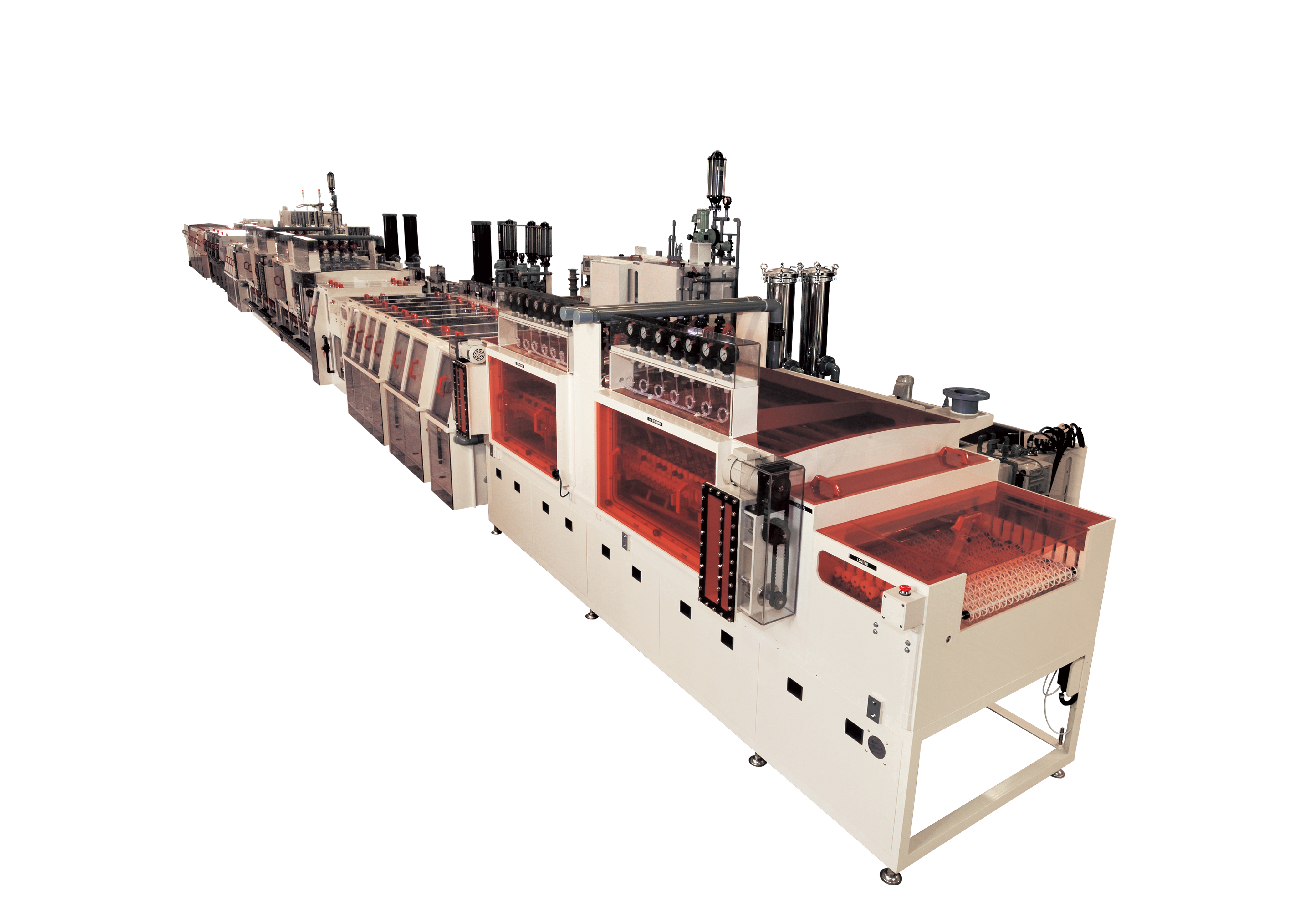

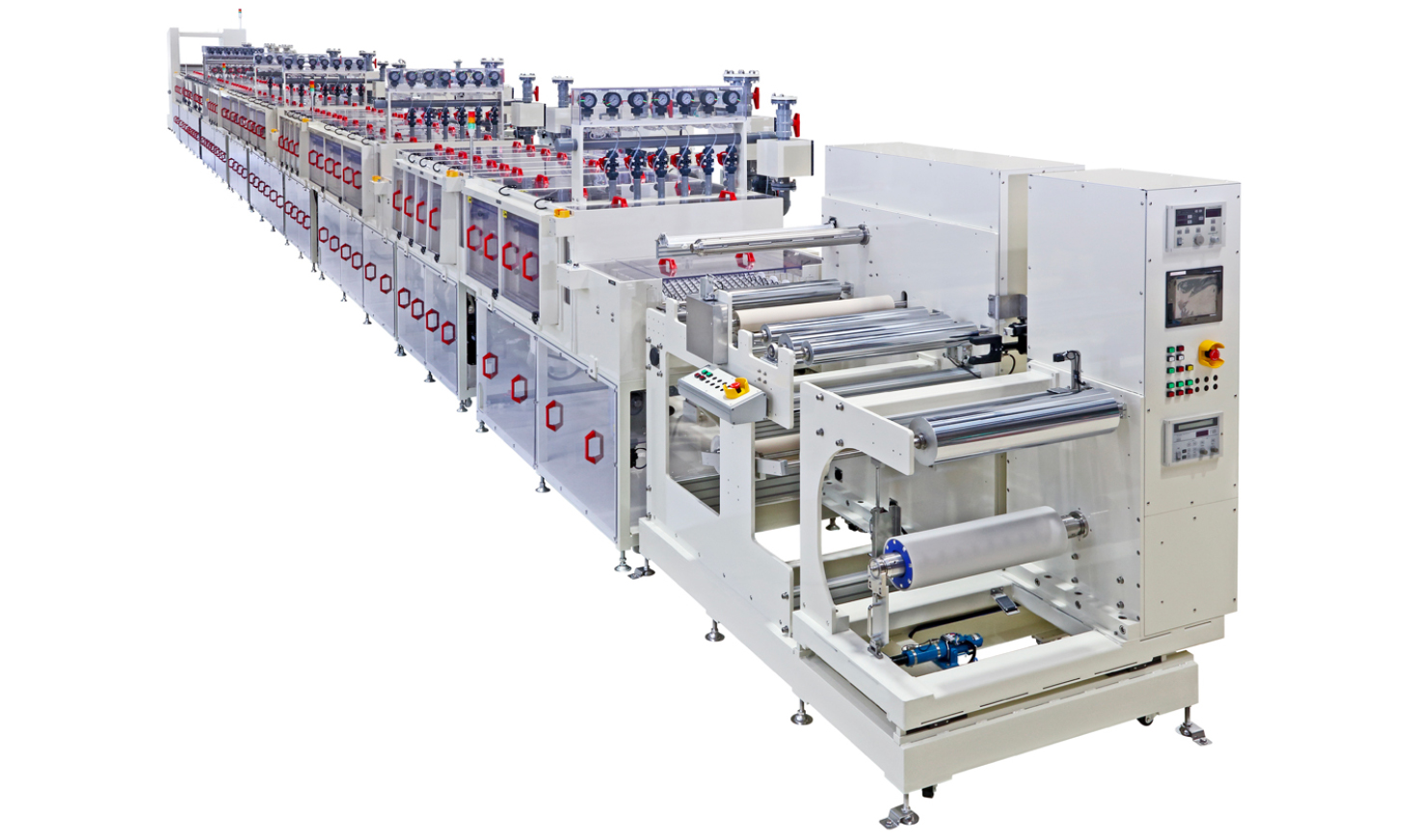

- PCB manufacturing equipment

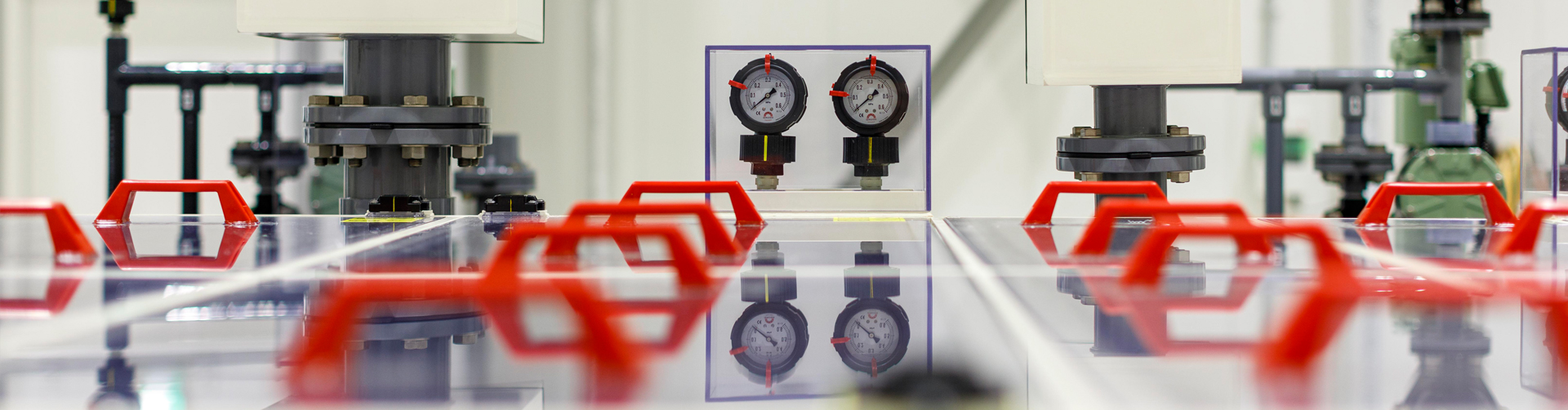

- The realization of distinguished surface accuracy by ideal nozzle arrangement High surface accuracy by refined technology. To strike a balance between quality improvement and cost down by automatic preparative and chemicals control system. The realization of high-precision L/S by the densification

●Pretreatment process

- Black oxide alternative horizontal processing equipment

- Micro etching equipment

- Soft etch small diameter hole cleaning equipment

- Etch-down equipment

●Photo-line

- Developing equipment

- Etching equipment

- Stripping equipment

- DES line

●Others

- Cleaning equipment (Ultrasonic, Air Atomizing spray, etc.)

See details

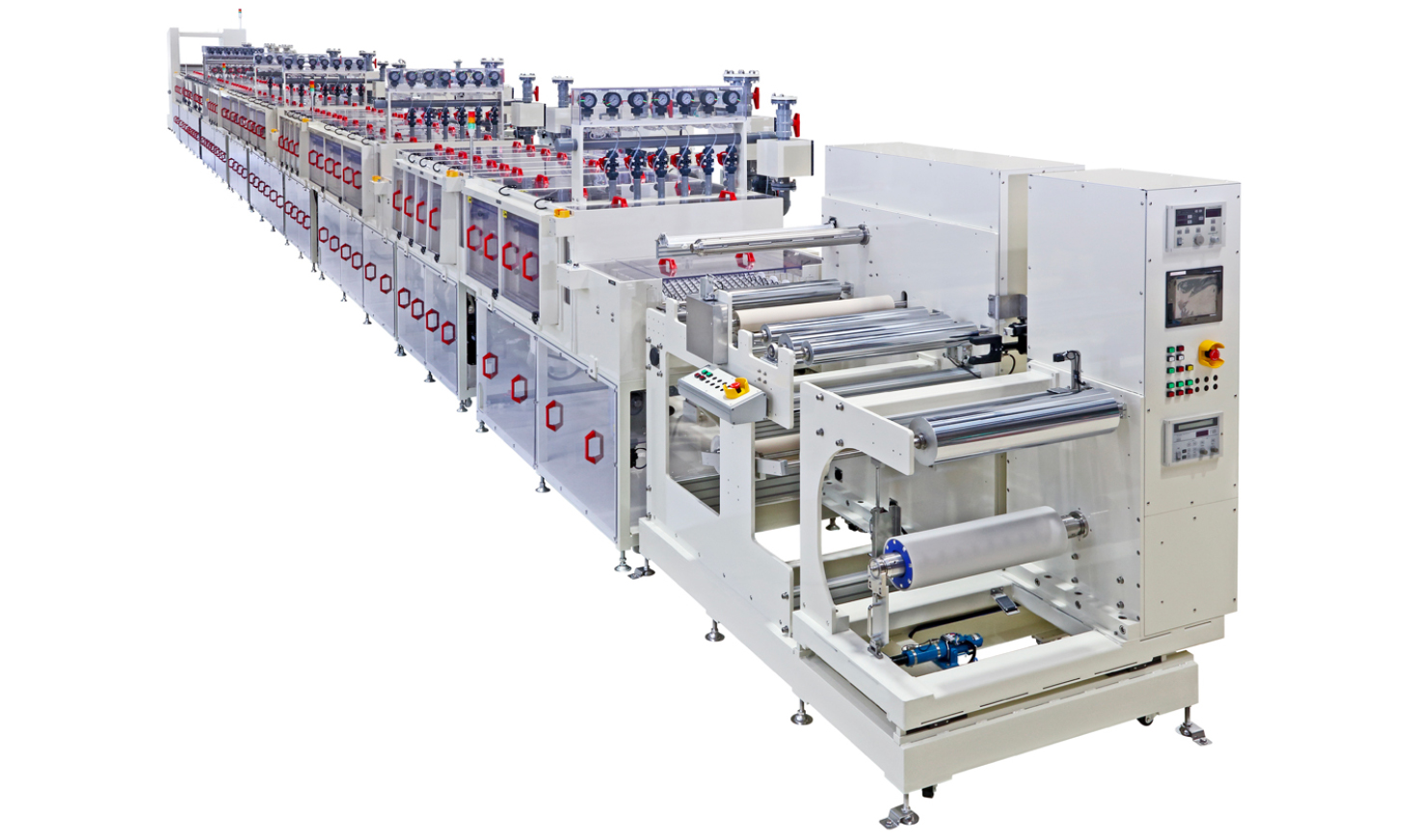

- Touch panel manufacturing equipment

- Equipment for developing, etching, and stripping various metals including ITO for manufacturing film and glass touch panels.

●Film touch panel manufacturing equipment

●Glass touch panel manufacturing equipment

●Others

See details

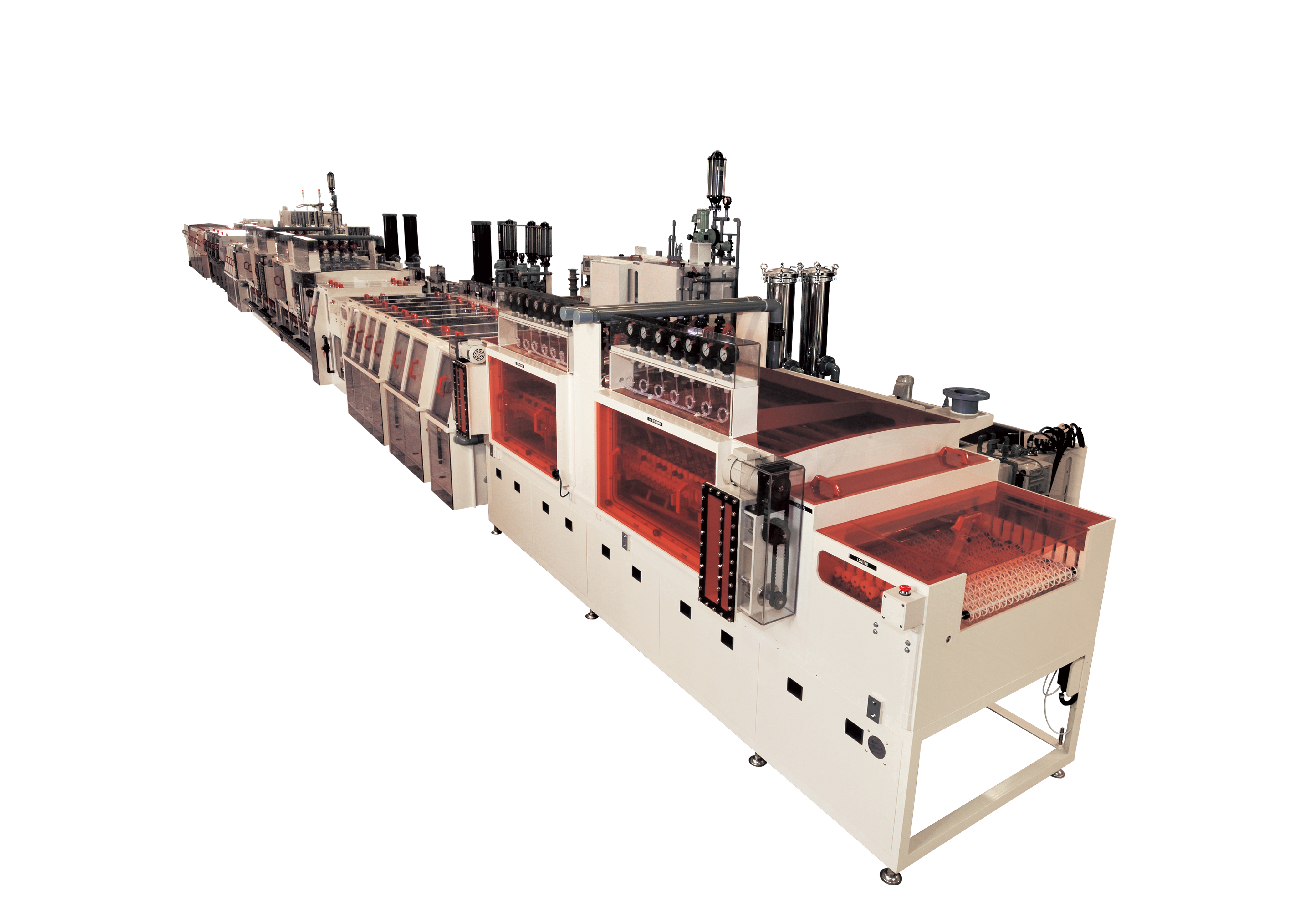

- FPD manufacturing equipment

- We have an assortment of photolines and pre and post wet equipment for flat panel displays.

●Pretreatment process

- Thin glass plate cleaning equipment

- Super High-pressure precision cleaning equipment

- ultrasonic wave cleaning equipment

- Roll Brush Cleaning Equipment

- Air Atomizing cleaning equipment

●Photo-line

- Glass board developing equipment

- ITO etching equipment (DES line)

- Al etching → Amine stripping equipment

- Various metal etching lines

●Other

See details

- Research and development

- A compact developing equipment is a device for developing resist coated on a board after exposure. While rotating the board, a reciprocating nozzle injects the developer solution from the top of the board, and the developing with developer solution, washing with pure water, and spin drying can be performed automatically by program control.

Stripping equipment is used in the TFT process to remove photoresist that has finished its role as a mask in the etching process using a chemical solution.

●ED series

- Economic simple type|Small-size developing / Etching / Stripping machines

●SP series

- Horizontally oscillating one-time pressure control type|Small-size developing / Etching / Stripping machines

●HP series

- Horizontally-oscillating stand ?alone pressure control type|Small-size developing / Etching / Stripping machines

●FB series

- Type for thin board and small size work|Small-size developing / etching / stripping machines for thin board

●MP series

- Oscillating stand-alone pressure control type|Small-size super high-precision developing / etching / stripping machines

●TS series

- Micro miniature simple type|Super small-size developing / etching / stripping test machines

See details